The purpose of cloth inspection is to make the finished garment produce as few defective products as possible. When fabric enters the factory, custom gym wear manufacturers first check the quality and quantity of the fabric. If it is not qualified, you can negotiate with the incoming unit to demand compensation or return. Otherwise, it wil affect the quality of activewear clothing and is not conducive to corporate reputation and interests.

Q 1. What to check when doing cloth inspection?

- A. Width fabric

In the process of printing and dyeing processing, it is inevitable to be subjected to mechanical tension, if the force of each section is uneven, or the drying is not thorough, it will cause the fabric to shrink unevenly, so that the width changes. Therefore, garment factories should re-measure the maximum width (Bmx) and minimum width (Bmin) of the same fabric and mark them accordingly. If Bmin is too small, there will be a shortage of parts, affecting production and causing unnecessary waste.

For the same fabric, there will also be differences in width between horses. This is not only related to printing and dyeing processing, but also has a considerable relationship with the different machines used when weaving fabrics. For fabrics of different horses, the width (B) of each horse should be measured and recorded. The technical department can separate the fabrics of different widths according to the corresponding report, and the large ones can be laid out in large garments, which is very beneficial for saving fabrics.

- B.Defects

Defects on the fabric have a direct impact on the appearance of the finished garment, and if the defects on the High End Workout Clothes are too many or more serious, the product will be downgraded or scrapped. Therefore, the inspection of fabric defects before production can not only detect defects before cutting, reduce the cost of changing sheets, but also reduce the workload of film inspection.

Defects in fabrics are generally generated during weaving, dyeing and finishing, and transportation.

(1) Weaving defects: such as bamboo yarn, roving, skipping yarn, warp break (weft), double warp (weft), holes, etc., as well as stains caused by engine oil or other pollution during weaving.

(2) Dyeing and finishing defects: such as color flowers, embrittlement, color matching, missing printing, dequalifying, etc. In addition, color difference, improper silk, uneven width and narrowness are all dyeing and finishing defects.

(3) Stains, breakages and other defects that occur during transportation.

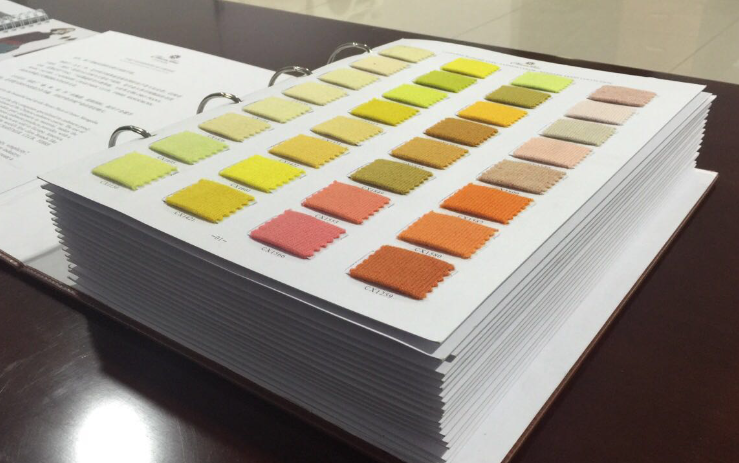

- C.Color aberration

When the grey fabric is printed and dyed, there will be a certain difference in color between the fabrics, even between the same fabrics. This is related to many factors such as dyeing equipment and conditions at the time of fabric addition, dye blending method, and so on.

If the fabric with serious color difference happens to be made into a garment, such as custom brand t shirts, it will make the overall color of the clothing different, and reduce the grade of the wide clothing.

How to do cloth inspection?

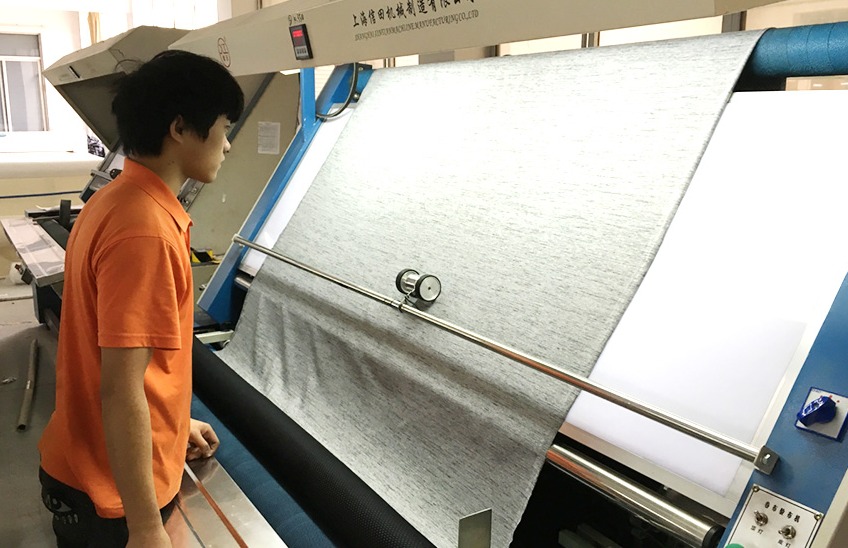

Custom Womens Clothing Factory inspects fabrics mainly by using fabric inspection machines or fabric inspection tables to analyze and judge the quality of fabrics according to human senses (eyes and hands). Therefore, the evaluation of fabric quality is still subjective and has a human factor. The results of the inspection depend on the actual experience, professional skills, and level of concentration and responsibility of the inspector.

The trend of cloth inspection method is to gradually adopt automatic cloth inspection machine, reduce human factors, reduce the labor intensity of inspectors, and at the same time, improve the efficiency and accuracy of cloth inspection.

What are the requirements for cloth inspection?

(1) The inspection bench should have good natural lighting or artificial lighting. The fluorescent lamp should be hung in the grooved light guide device to avoid light and affect the lighting effect. In order to avoid the reflection of the inspection screen from direct sunlight, transparent curtains can be used to block it.

(2) In general, the surface quality of the fabric should be inspected from the front. Only in a few cases, such as fabrics that can be used on both sides, should be inspected from both sides.

(3) Marking. In order to make it easier to find when trimming fabrics or parts, it is required to mark different fabrics in different ways during the inspection process. For example: coats and suit fabrics, use chalk to mark the defects, and use cloth strips on the edges of the block.

In addition, the degree of color difference, width and width of the fabric, weft and weft bend should be indicated.

(4) Determine the quality level of the fabric. The tested fabric should indicate the grade (such as appearance grade score) and physical and chemical characteristics (such as shrinkage, washing resistance, sun fastness, etc.) of the fabric as the basis for evaluating the fabric.